Address: Group B5-4, Small and Medium-sized Enterprises Incubation Park, Shawen Eco-science and Technology Industrial Park, Guiyang High-tech Industrial Development Zone, Guizhou Province

Website: http://www.ad-lib.cn

Tel: 0086-0851- 88114270กข17885921423

Fax: 0086-0851-88114270

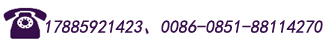

At 10 a.m. yesterday, the Ministry of Industry and Information Technology of South Korea announced the results of the previous 23 energy storage incidents fire investigation.

To some extent, the investigation of this accident can also help us understand some problems and provide some reference for our energy storage and the long-term use of electric vehicles.

Note: The high incidence of energy storage accidents is actually related to its use environment. In view of the distribution of energy storage power stations in Korea, the application environment of energy storage is actually very poor.

Causes of Energy Storage Fire Accident

After discussion, analysis, organization and synthesis of relevant information, including PCS manufacturing, ESS battery system design, installation and construction, use and fire related reasons, including electrical and environmental factors, summed up the following reasons:

Defects of Europium Battery System

Insufficient Protection System for Insulation Detection

Insufficient management and maintenance after construction of Sha Energy Storage Power Station

The integrated management system between PCS and ESS is not good

Investigation and analysis process

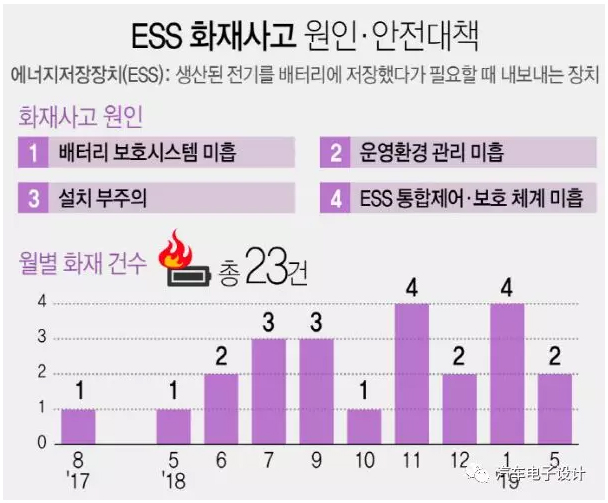

1) Battery system defects

Battery disassembly analysis confirms that there are some defects in the battery production process, and that many accidents use the same batch of batteries produced in the same factory. The results showed that the coating of active substances on the electrodes of these batches was not good.

Note: The following is the dismantling of batteries produced in the same batch as accident batteries.

Causes of Energy Storage Fire Accident

After discussion, analysis, organization and synthesis of relevant information, including PCS manufacturing, ESS battery system design, installation and construction, use and fire related reasons, including electrical and environmental factors, summed up the following reasons:

Defects of Europium Battery System

Insufficient Protection System for Insulation Detection

Insufficient management and maintenance after construction of Sha Energy Storage Power Station

The integrated management system between PCS and ESS is not good

Investigation and analysis process

1) Battery system defects

Battery disassembly analysis confirms that there are some defects in the battery production process, and that many accidents use the same batch of batteries produced in the same factory. The results showed that the coating of active substances on the electrodes of these batches was not good.

Note: The following is the dismantling of batteries produced in the same batch as accident batteries.

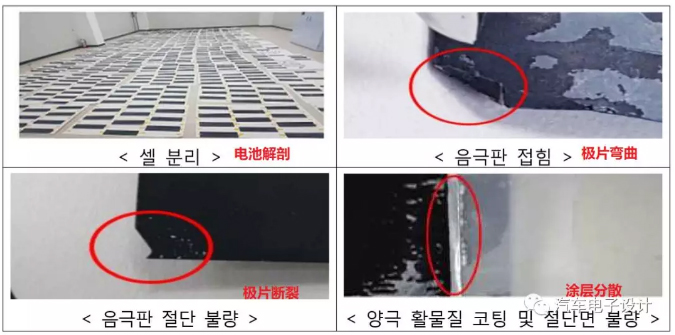

3) Insufficient management and maintenance of energy storage power station after construction

Moisture and Dust Testing: Based on the detection of melting marks around the air conditioner, the possibility of reducing insulation performance is tested by simulating the environment of water, dust and brine on the battery system. Fire occurs when performance deteriorates.

Note: There is no problem with temperature alternation test and lightning surge.

4) The integrated management system between PCS and ESS is not good

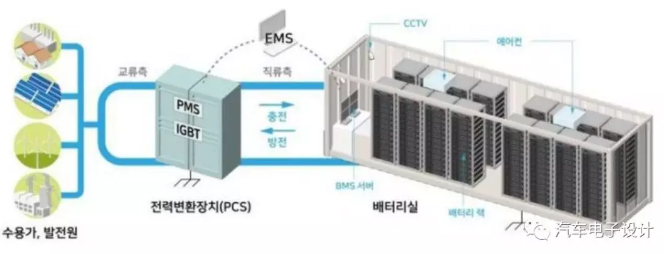

In the investigation, it was found that the information sharing between BMS, PMS and EMS was not well done by the maintenance staff. PCS did not coordinate well with the operation sequence of battery protection system. The system was restarted without checking the battery status after PCS troubleshooting, which led to the conflict between AC side and DC side of the system.

ESS Fire Accident Investigation Results

(1) Battery protection system is inadequate: When battery abuse occurs, such as grounding fault or overcurrent, the fuse of battery system does not cut off the current quickly, which leads to the deterioration of DC contactor and the secondary short circuit of Busbar and rack, and causes fire.

(2) Poor management of operating environment: Battery system exposed to a lot of dust and condensate in mountainous and coastal areas where ESS is installed

Condensate + dust form a damage to insulation, leading to local short circuit, may cause fire

Some use air-cooled fans, which can increase the spread of moisture and dust.

Installation and management: Battery storage problems or wiring errors confirm that fire may occur.

(4) Insufficient comprehensive management: EMS, PMS and BMS are products of different companies, so they can not integrate the system organically.

_Some defects found in batteries, micro-short circuit in batteries may increase the probability of fire occurrence.

Summary: This Korean report makes me tired. Several factors are valuable, such as the secondary short circuit of Busbar caused by overcurrent under the fuse threshold, and the local short circuit caused by water entering the battery system. When the battery loses IP protection, it is under the action of dust, salt and water. More headache

Address: Group B5-4, Small and Medium-sized Enterprises Incubation Park, Shawen Eco-science and Technology Industrial Park,

Guiyang High-tech Industrial Development Zone, Guizhou Province

Website: http://www.ad-lib.cn Tel: 0086-0851- 88114270กข17885921423 Fax: 0086-0851-88114270